There are various printing techniques used for modern day commercial printing. Most popular are Flexographic Printing and Rotogravure Printing which commonly refers as Gravure Printing.

This article explains the details about Flexo Printing vs Gravure Printing. This will help you to choose from Rotogravure Printing Machine and Flexo Printing Machine as per your application.

Flexo Printing Vs. Gravure Printing

We discussed advantage and disadvantage of Flexo printing machine and Rotogravure Printing Machine in several affecting factors such as:

- Cost and Lead Time

- Substrates

- Ink

- Quality

- Effect on Environment

Flexo Printing

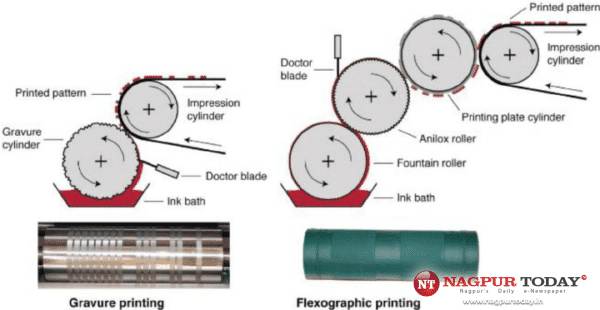

Flexographic uses polymer or elastomer image carrier which could be a sleeve, a cylinder or a plate.

Here the image carrier is engraved for creating a raised design for the final print.First the ink is transferred from inkwell by anilox roller on image carrier. Then it is printed on substrate.

The flexographic printing machine is used for flexible plastics and other non-porous materials like film, labels, foil and other packaging materials.

Flexo printing is used for repetitive print with text and line details.

Rotogravure Printing

It is a intaglio printing process. In this process the ink is applied on the substrate by metal plate which is mounted on the cylinder. The metal plate is made from copper or chrome. The image or text on the roller for printing is laser etched. This gravure printing gives best results for repeated printing with precision and high quality.

Similarities

Before we discuss the differences, first look at the similarities.

- Both the printing methods use of sleeves, cylinders and plates for printing.

- Both are capable for long-run, high-volume printing. The flexo printing is cost-effective option.

- Gravure and flexographic printing produce exceptional printing results.

Cost and Lead Time

The rotogravure image carrier is expensive than flexographic image carries. However, gravure printing has longer press run time as there is no frequent changes require of cylinders compared to flexo printing.

The rotogravure lead time is 3 to 4 times more than flexo to produce image carrier.

Substrate

The rotogravure printing is generally suited for porous substrates which makes it suitable for high detail printing such as magazine covers.

This is not the same for the flexo printing and able to print onporous and non-porous substrates. That makes it ideal for printing on various materials from film to paperboard. For the packaging printing the flexographic printing is bit ahead than rotogravure printing.

Inks

The next different between Flexographic Printing Machine and Rotogravure Printing Machine is the ink used in. There is limited number of inks can be used with rotogravure printing while variety of inks can be used with flexo printing.

Also, the rotogravure printing uses more ink per print compare to opposite one which increase the cost of printing.

Quality

Before flexo the gravure is considered as best for detail and tonal work now the flexo prints with high resolution and detail and can print difficult jobs before which is only achievable by gravure.

Effect on Environment

Gravure uses solvent-based inks. There is ongoing research for water-based ink for rotogravure inks. On the other hand, the flexo are uses greener products to print.

Which one to Choose?

Flexographic Printing Machine vs Rotogravure Printing Machine, which one to choose? Well, it is highly depends on the job, substrate and multiple different factors.